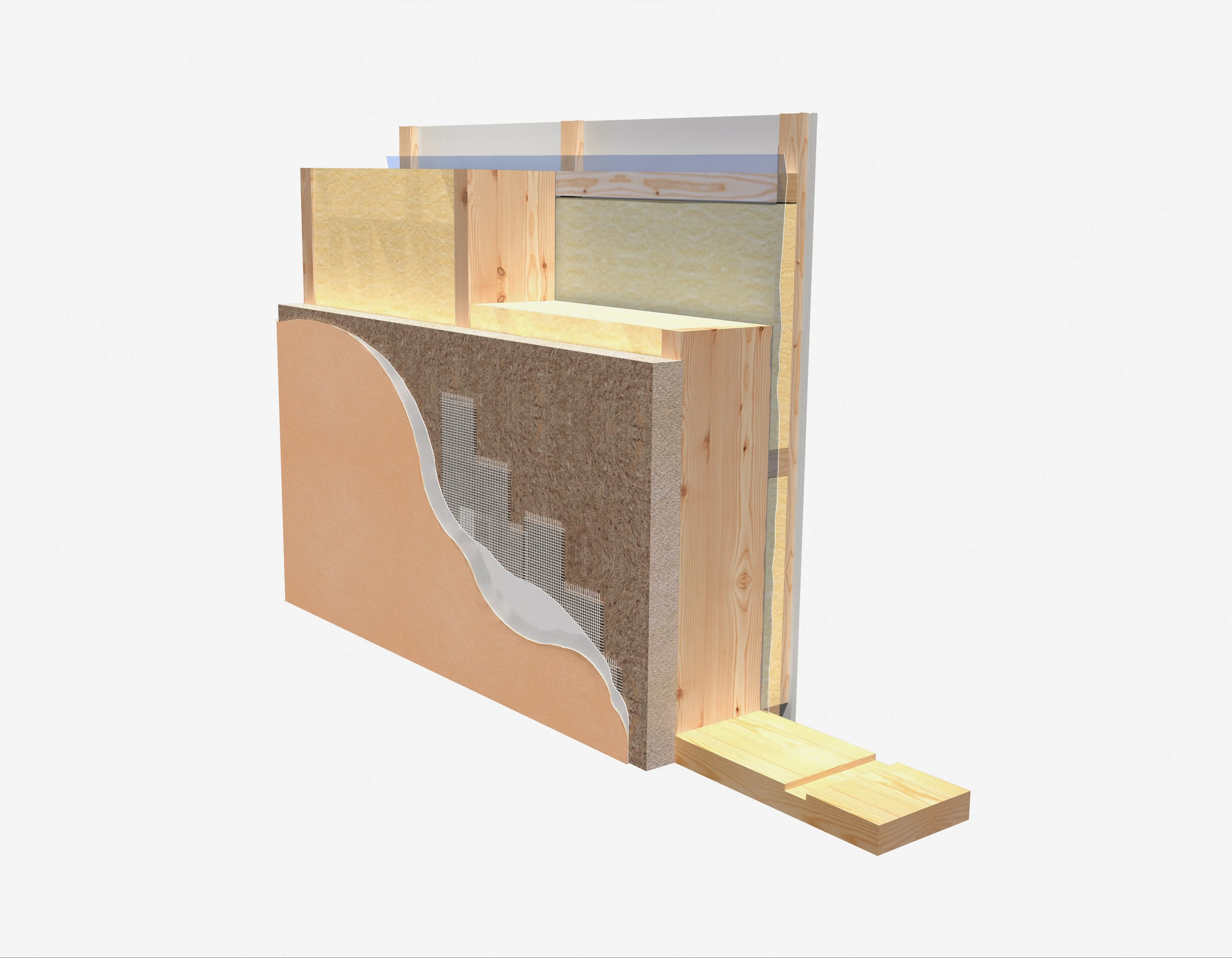

We offer external wall elements with either plaster or stone imitation for facade finishing.

The main construction consists of a wooden frame (145 mm, 195 mm or 220 mm) and wooden extra insulation slats (45 mm) with extra insulation material on the internal side of the wall.

For the external side of the wall for your prefabricated house, you can choose, for example, a plastered mineral insulation board(100 m).

All this will give you wall elements with excellent thermal resistance resulting in wall construction with a U-value of 0,13 W/m²K.

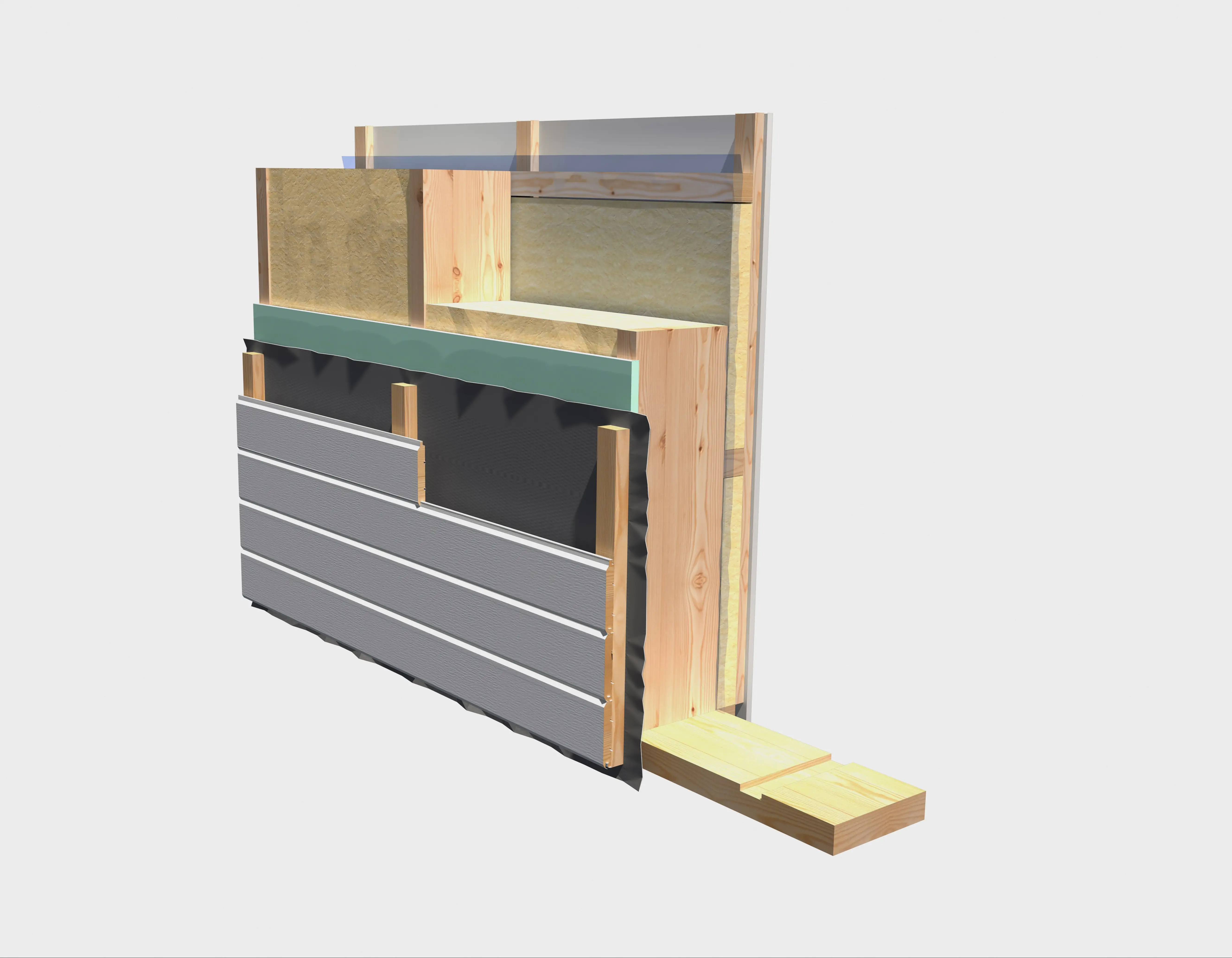

We offer external wall elements with wooden panelling for facade finishing.

The main construction consists of a wooden frame (145 mm, 195 mm or 220 mm) and wooden extra insulation slats (45 mm) with extra insulation material on the internal side of the wall.

For the external side of the wall, you can choose wooden panelling of different profiles and installation directions.

All this will give you wall elements with excellent thermal resistance resulting in wall construction with a U-value of 0,16 W/m²K.

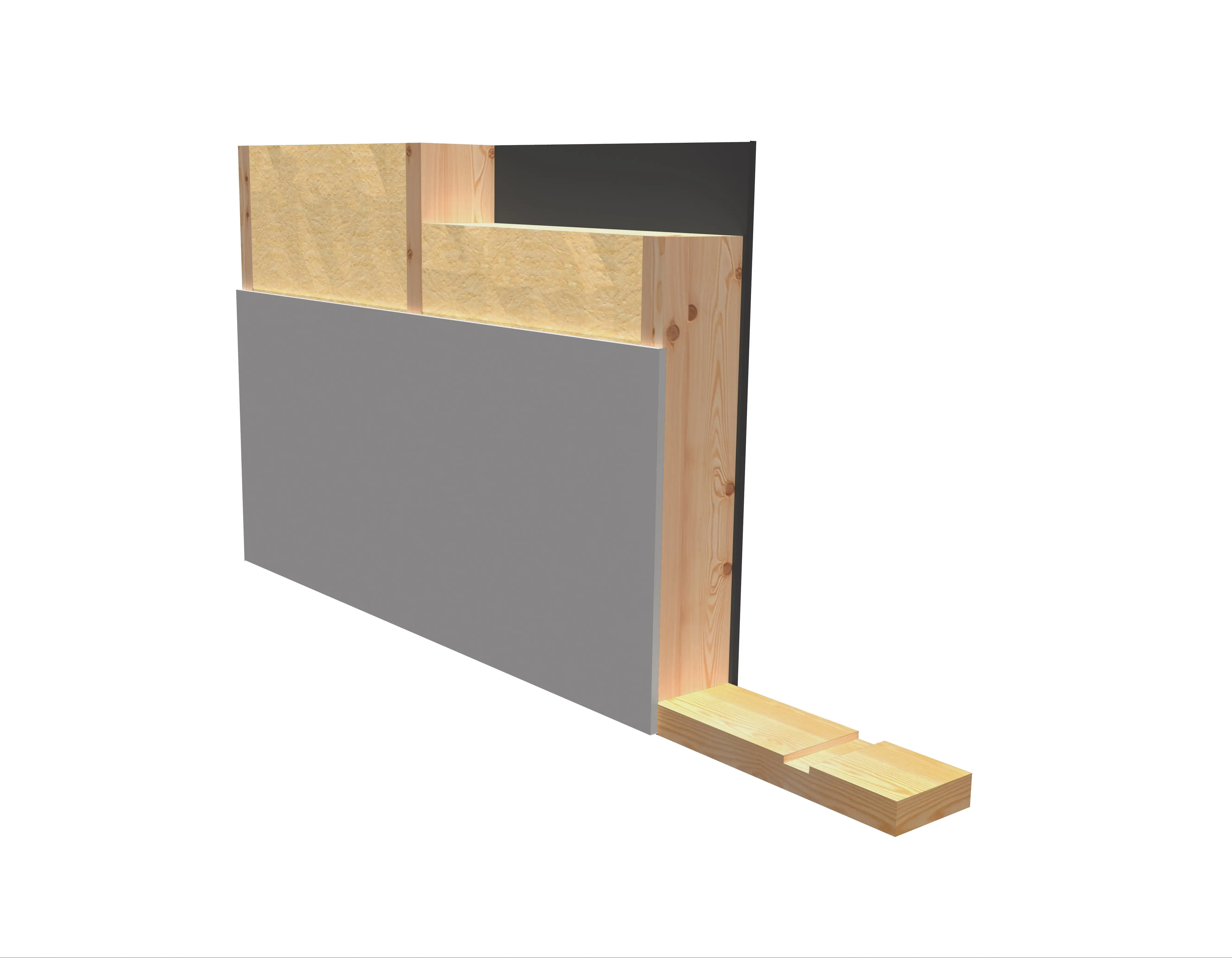

Prefab internal wall elements are divided in three groups:

Load-bearing internal wall elements usually consist of either a 120 mm or 145 mm wooden frame. Isolation is added to the frame for soundproofing, OSB boards if necessary and finally, plasterboards on both sides of the wall.

Non-load-bearing internal wall elements usually consist of either a 70 mm or 95 mm wooden frame. Isolation is added to the frame for soundproofing, OSB boards if necessary and finally, plasterboards on both sides of the wall.

The internal walls between apartments are so-called double walls. This means that the wall consists of two wall elements with air space in between. Both wall elements are covered with double plasterboards on the internal side of the wall.

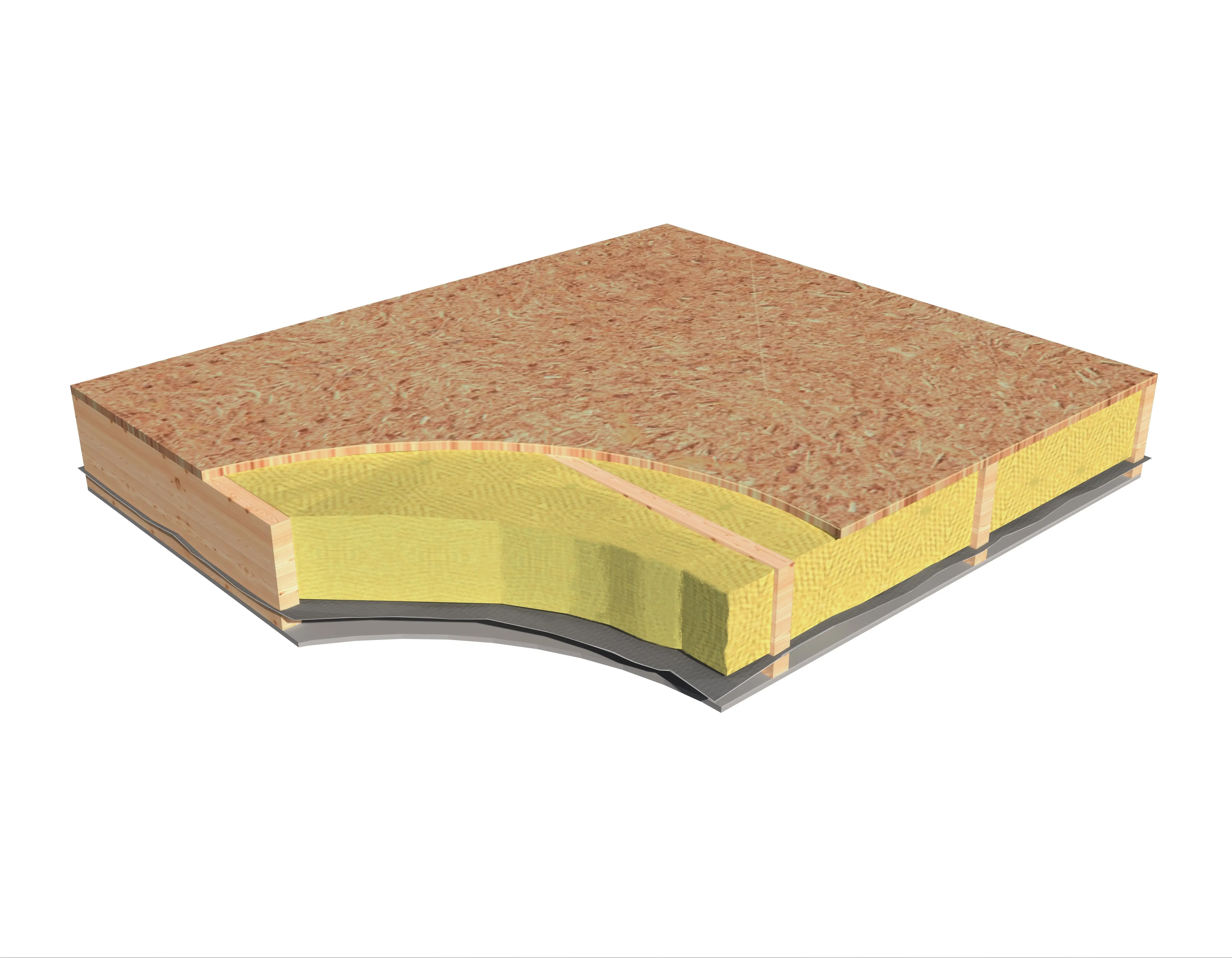

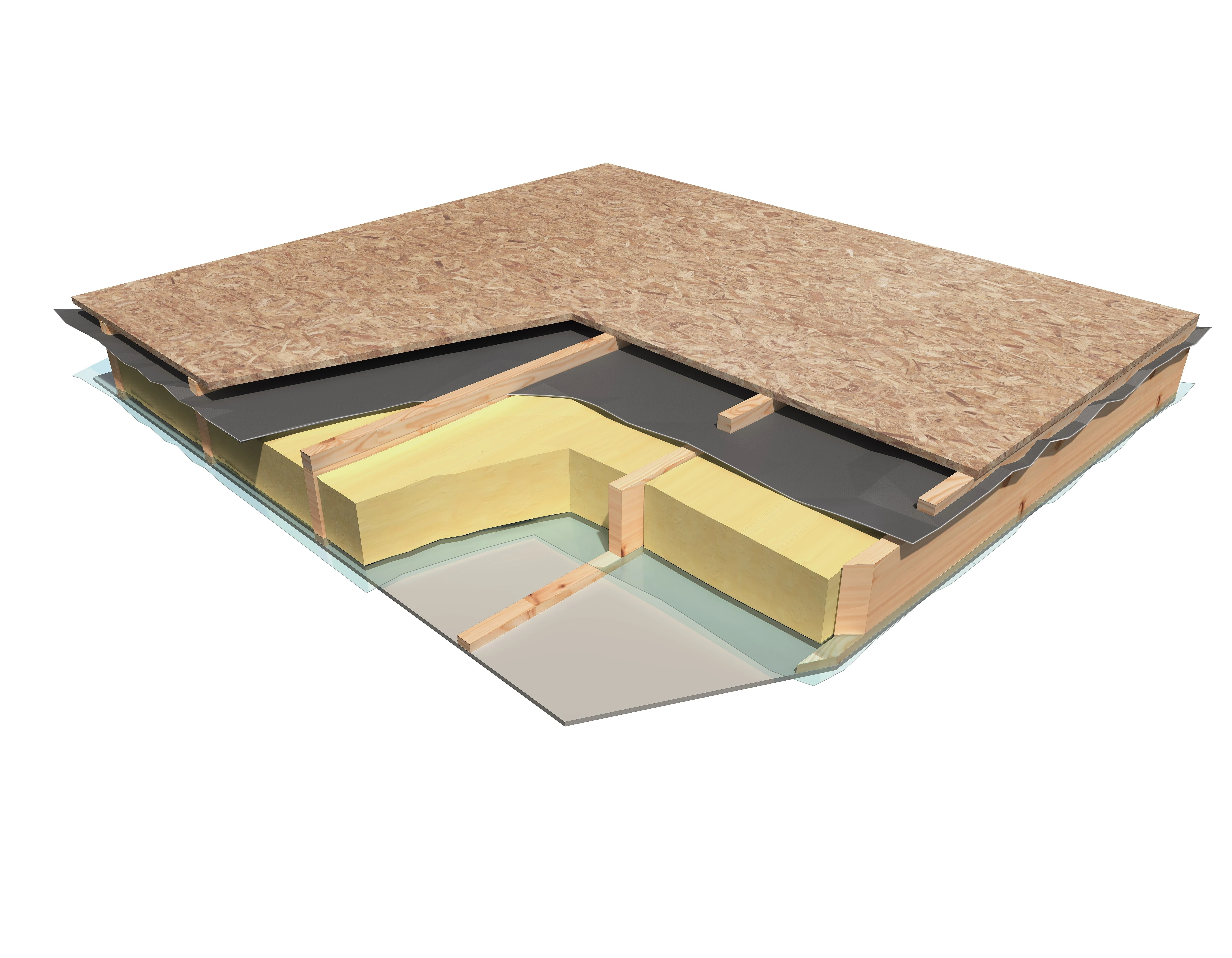

Prefab inserted ceiling elements usually consist of either a 145 mm or 195 mm wooden frame.

On the top (meaning on the first-floor side), the element is covered with a 22 mm OSB board, where it is easy to install any floor materials of your choosing.

On the bottom (meaning on the ground floor ceiling side), the prebuilt elements are covered with a vapour barrier and installation slats. The installation slats are covered with plasterboards or wooden panelling on the construction site.

Inside the prebuilt elements, there is either 150 mm or 200 mm insulation for soundproofing.

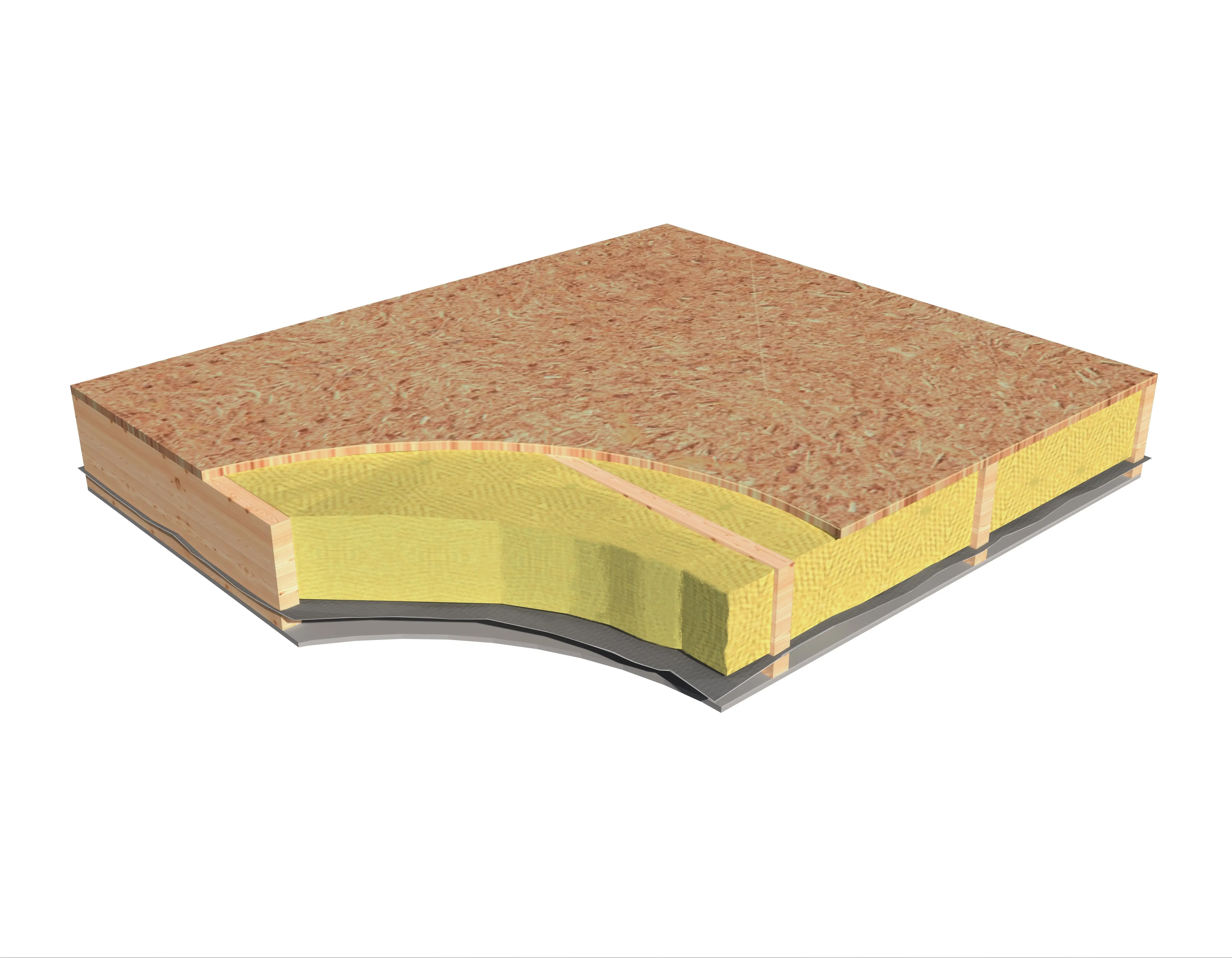

Prefab floor elements usually consist of 145 mm or 195 mm floor joists with either 150 mm or 200 mm insulation installed in the floor construction.

The bottom side of the floor element is covered with moisture-resistant plywood or wind barrier fabric.

The top of the floor element is covered with a vapour barrier on which a 22 mm OSB board is installed. It is easy to install any floor materials of your choosing on the OSB board.

To achieve even better thermal resistance, it is possible to add extra insulation slats up to 95 mm with 100 mm insulation. This construction has a thermal resistance of 0,13 W/m²K.

Prefab roof elements usually consist of rafters beginning from 195mm. It is possible to use double rafters, which are joined together by barb connector plates, thanks to which we can offer roof elements with excellent thermal resistance.

The bottom side of the rafters is covered with a vapour barrier on which either 45 mm or 95 mm extra insulation slats are installed. This part is also filled with insulation to further improve the thermal resistance of the roof element. The extra insulation slats can be covered later with either plasterboards or wooden panelling.

On top of the rafters, a breathable membrane is installed, which also acts as a wind barrier fabric. Ventilation slats and 22 mm OSB boards are installed on the roof.