Log house Aare is a modern looking two-storey family dwelling with a spacious living room and dining area.

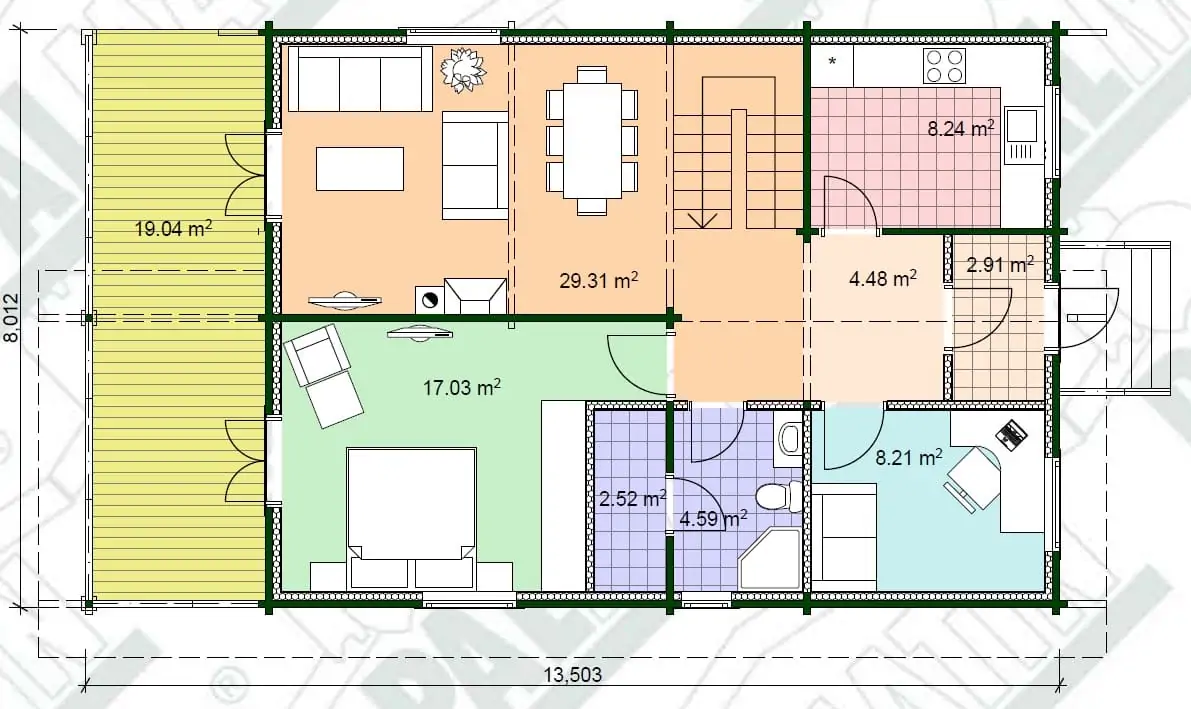

On the ground floor there is a separate kitchen which allows more privacy. Opposite the kitchen is an office, which is great for some quiet working. Next to the office is a cosy bathroom with a sauna. Also on the ground floor is the master bedroom with access to the terrace.

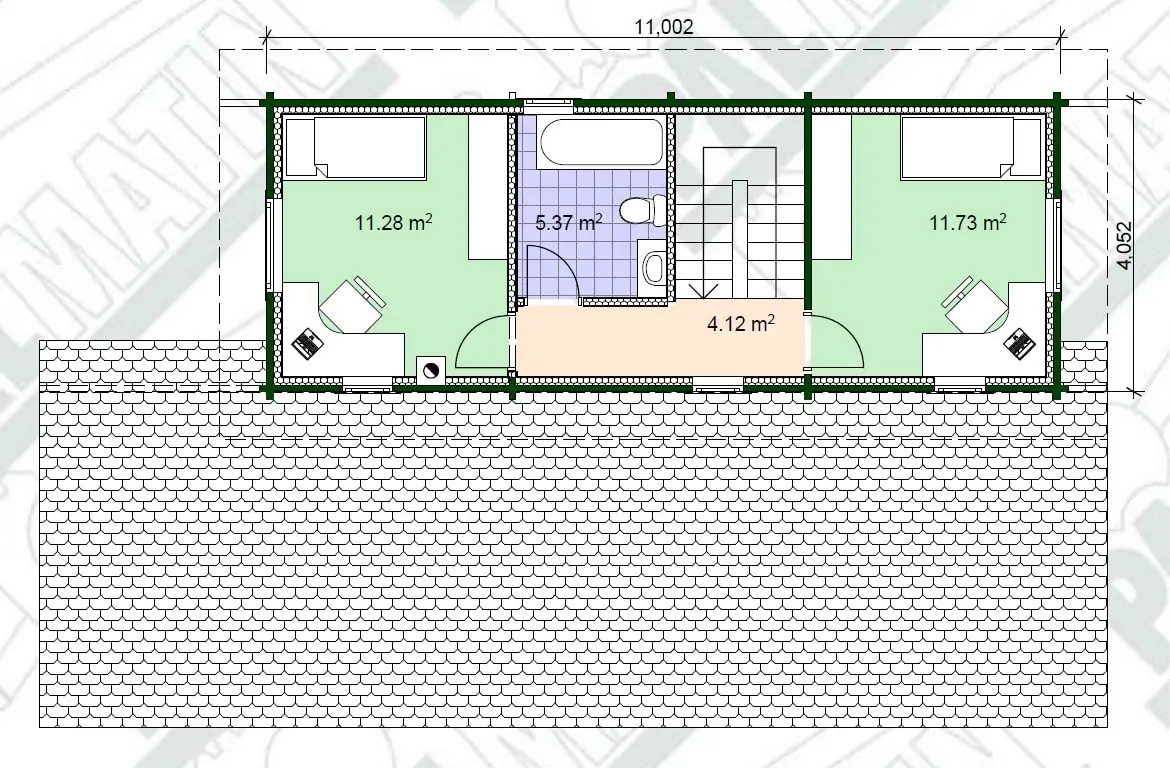

On the first floor there are 2 more bedrooms and another bathroom.

Get an instant quote for full price info and details below.

Instant, 3-second price quote!

"*" indicates required fields

PALMATIN CUSTOMER STORY

We selected Palmatin thanks to fast feedback and informational webpage. There were a lot of house plans and projects. Many other log house companies didn’t offer drawings. We asked price offers from 7 to 8 companies and only received two price offers – one was from Palmatin.

It is possible to use different stone materials as wall coverings. It is possible to choose from brick, decorative stone, etc. If you use stone as your external wall covering, a special cement board is installed on the prefabricated wall and the stone material will be installed thereupon on the site. In the case of stone covering, a wider foundation must be built to support the wall covering.

It is similar to a stone facade, a special cement board will be installed on the prefabricated walls. The rendering of the facade will take place on the site.

With wooden facade you have many additional options. You may choose between different cladding profiles, types of wood and the manners of treatment of the wood (varnished, painted, impregnated, etc.) Treated wooden cladding will be installed on the prefabricated walls at the factory.

Basic – includes drawings for the log part, log part of the house, T-battens for openings, hydro isolation between the foundation and first log row, wooden dowels, isolation between the logs, special metallic parts and packages to be delivered in the order of assembly. The Basic kit is suitable if you wish to buy only the walls of the house and build the rest of the house yourself.

Standard – in addition to the Basic kit, this kit includes rafters, roof hydro isolation, ventilation slats, sarking, first floor joists, balcony joists, windows, exterior doors and special metallic accessories. The Standard kit is suitable if you wish to get a weatherproof house quickly and then continue with interior works in your own pace.

Premium – in addition to the Standard kit, this kit includes all other wooden materials needed to finish the house, interior doors and a staircase. The Premium kit is the most comfortable kit, including all wooden materials needed to build a house. This is suitable if you wish to finish the house quickly without spending time worrying about the quantity or availability of materials.

Do you have questions about the house or would like to consult about your next project? We'd be happy to answer all your questions!

Jaan Köönvere

+372 605 48 95

Before reaching the construction site, only the round logs are treated at the factory. It is also possible to treat the wood before the arrival of the house on the construction site. The treatment at the factory is an option.

The site has to have access roads for heavy trucks, the foundation should be ready and the ground smoothed.

Building a wooden house or prefabricated house on a construction site requires preliminary preparations and the availability of machines. You should first be ensured that the necessary and common tools (hammer, screwdrivers…) can be provided. To unload and move the log and prefabricated elements, a crane is necessary. A waste container might be placed to keep the site clean. Works-at-height have to be realized on a secured scaffolding. If a team is present on the construction site, additional material might be needed. Palmatin provides in advance the instructions and advice to prepare correctly the construction site.

One of our objectives at Palmatin is to provide our clients with quality and affordable products, as the price of the houses should not control the quality of the products. To do so, we select and purchase the raw materials. We establish contact with our clients and work with them on their projects. We also monitor all stages of the manufacturing process. We assist our clients until the house assembly is completed. This process management allows us to manage our costs. Direct purchase and sales, without intermediaries, and efficient controlled production is one of the keys to a good price-quality ratio.